5 Strategies loggers and contractors are using to boost safety and productivity while managing ongoing costs

In the tough industry of logging and contracting, safety and productivity are paramount. To achieve these goals, contractors across a variety of countries such as New Zealand, Pacific Northwest and Canada have embraced innovative strategies to manage winch assisting operations efficiently. We look at the top five effective methods that loggers and contractors are implementing without compromising productivity. From cost-sharing to the correct structured financing, these practices are enhancing safety while maximizing output.

1. Splitting the Cost of New Equipment Over Multiple Crews (Operations)

Investing in new equipment can be financially burdensome when looking at crews in isolation. To overcome this challenge, contractors have opted for a collaborative approach by splitting the cost of winch assistance equipment across multiple crews. By sharing the capital cost, each crew benefits from the advanced machinery without jeopardising their budgets. This cooperative model maintains productivity for the machine and enables smaller operations to access the tethering and winch assist technology, promoting safety and productivity across the board without the full price-tag.

Benefits:

- The more crews you have, the more effective the strategy is.

- Keeps asset/equipment working efficiently.

- Spreads running costs across the business operation.

- Reduces running costs.

Considerations:

- May not be suitable for smaller crews (owner-contractors)

- Potentially not having a specific piece of equipment for every task.

- Time and scheduling of tasks of there’s an overlap in workload or processors.

- Locations of work could impact efficiencies in relation to transport.

2. Splitting Equipment's Use Over Multiple Processes

Instead of limiting equipment use to a single process such as extraction, loggers and contractors are capitalising on the Falcon Winch Assist versatility. The Falcon equipment can be utilised for various tasks, such as skidding, yarding, or loading out logs or material onto trucks. By splitting the equipment's use across different processes, contractors optimize its efficiency and productivity. This strategy minimises downtime and ensures that the winch is fully utilised throughout the work cycle, increasing overall productivity without sacrificing safety or incurring additional costs.

Benefits:

- Keeps asset/equipment working efficiently.

- Spreads running costs across the business operation.

- Reduces running costs.

Considerations:

- Potentially not having a specific piece of equipment for every task.

- Time and scheduling of tasks of there’s an overlap in workload or processors.

3. Finance Structuring the Right Way

*This is not financial advice and we recommend you speak to a trusted financial advisor for specific advice in relation to your situation.

Proper financial planning and structuring can significantly impact the affordability of winch assisting equipment. Loggers and contractors who have strong relationships with finance partners are likely to see better interest rates and opportunities to structure the finance in a way that is most effective and efficient to their operation. By tailored payment schedules, timeframes and considering lease-to-own agreements, finance partners align the contractors needs with their operational cash flows. This approach eliminates the need for significant upfront investments and provides flexibility for contractors to access winch assist benefits without substantial capital outlay.

Benefits:

- Helps keep debt efficient.

- Saves costs.

- Excellent way to minimise capital outlay.

- Lease-to-own solutions allow a plan for future purchase.

Considerations:

- May have less flexibility in time payback periods.

4. Negotiating Costs within the Supply Chain

Maintaining healthy relationships with forest management and planners is crucial for loggers and contractors to optimise their operations. By actively keeping the pre-operation aspect of the supply chain communication transparent it allows the opportunity to negotiate terms and prices, especially when there is benefit of winch assisting to the forest management and planners in the form of productivity, safety risk reduction and aligning with their own company values.

Benefits:

- Reducing direct costs on your operation.

- Allows a way to access the technology at a smaller price point.

- Helps build trust and relationships.

Considerations:

- Ton/day rate may be impacted.

- Competition for contracts.

5. Utilising on an as-needed Basis

To maximise efficiency and minimise costs, more and more smaller logging operators and contractors are embracing the concept of utilising winch assist systems on an as-needed basis. Rather than owning and maintaining equipment that may be underutilised, some contractors are opting for a lease option to maintain workflow and contract security. This approach allows contractors to access winch assistance equipment precisely when it's required, reducing idle time on equipment. By using equipment on-demand, loggers and contractors streamline their operations, boost productivity, and maintain high safety standards without incurring unnecessary expenses.

Benefits:

- Excellent for small contractors, long-term servicing costs are likely to be lower.

- No long-term

- Suitable if medium to long term uncertainty

- Allows flexibility in businesses direction/work

Considerations:

- Day-rate may be higher when factoring in long term-use.

- Transport costs need to be factored in for smaller time periods.

- May not be utilising the same machine on lease (subject to availability)

Summary

In summary, each contractor will have their own unique situation when looking at the workload, type of operation and equipment needed so considering these five strategies, loggers and contractors are able to structure their equipment purchases in a way that suits their business.

From sharing costs across crews and equipment use to smart financial planning and negotiations, these practices enable the industry to operate efficiently, ensuring safety while maximising productivity.

Share this

You May Also Like

These Related Stories

Steep slope conference a big hit

.jpg?width=676&height=451&name=wa150%20(11).jpg)

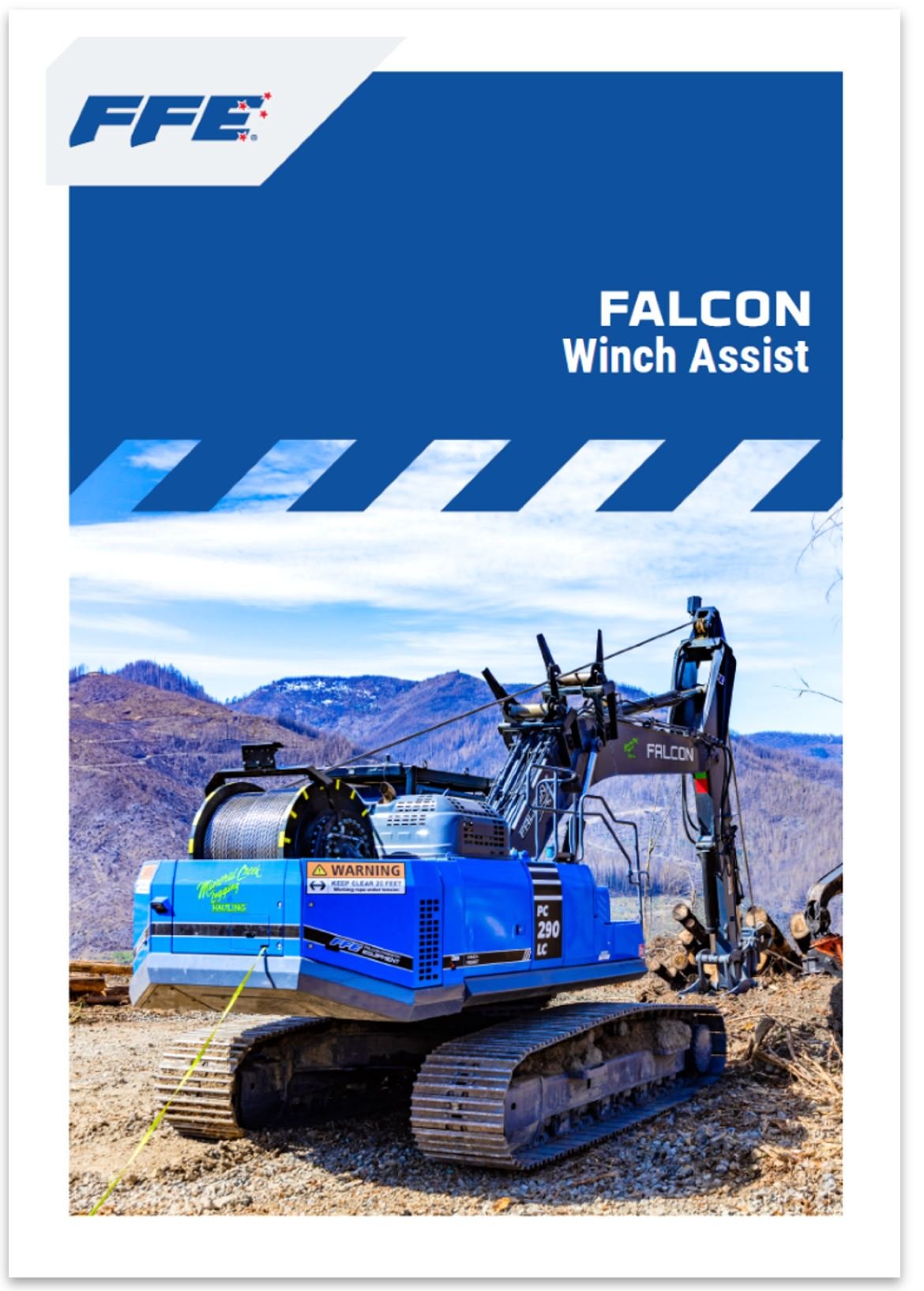

Falcon flies on the slopes